Polyurethane VS Rubber

The major advantage of molded polyurethanes over rubber is their abrasion resistance. It is the combination of high tear resistance and a high module that gives polyurethanes this advantage.

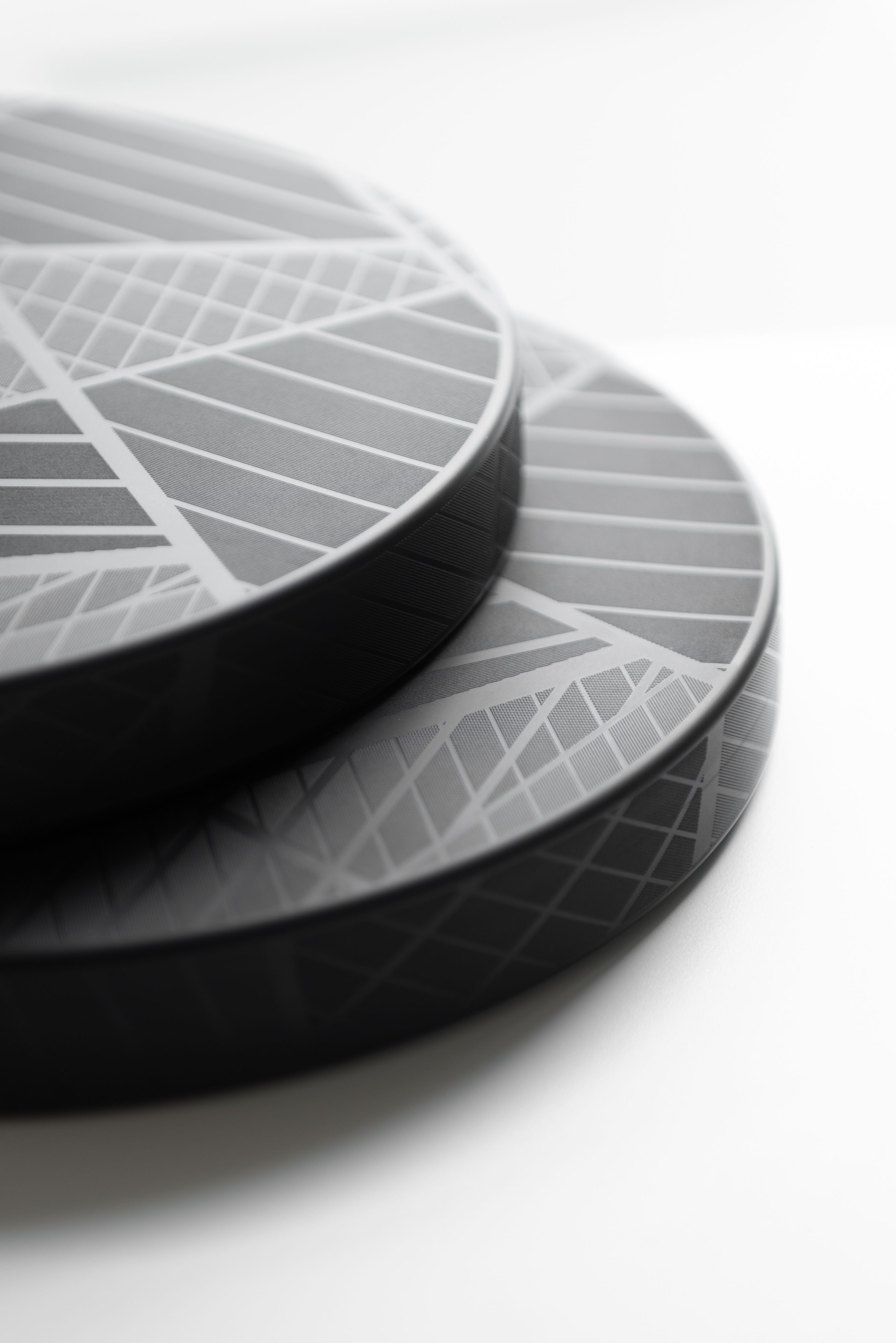

Other advantages are significantly lower casting costs, much wider durometer intervals, ozone resistance and the polyurethane can also be pigmented with different colors. With a selection of colors, different parts can be color-coded or possibly match the company’s logo.